Interview: Company staff of Aerodynamics for “Shitamachi Bobsleigh”

From the spring to early summer of 2016, the “Shitamachi Bobsleigh” project was proceeded with a new design. The “Shitamachi Bobsleigh” design had undergone several minor upgrades by then, but the full-model change would be for the second time since the production of Unit 2 and 3 for the Sochi Olympics.

For this model change, various aspects from aerodynamics to the details of the body frame were reviewed based on the data and experiences obtained from the previous improvements. Moreover, the tech team from Jamaican National Team joined the renewed “Shitamachi Bobsleigh” project. The following is a conversation with Mr. Fujiyama of Software Cradle, Co., Ltd. who works on the aerodynamics analysis for the design phase, about his daily work and about aerodynamics.

What is CFD

―To start with, what does Software Cradle do for business?

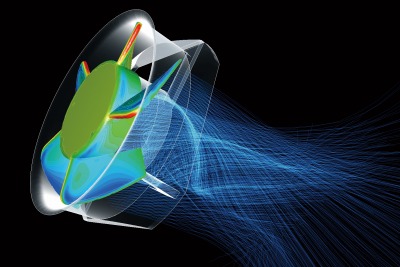

Fujiyama―We develop and sell software for CFD, or Computational Fluid Dynamics, which analyzes heat and flow. We also provide consulting for the use of the software and undertake thermo-fluid analysis operations.

― Can you elaborate on the technical term “CFD”?

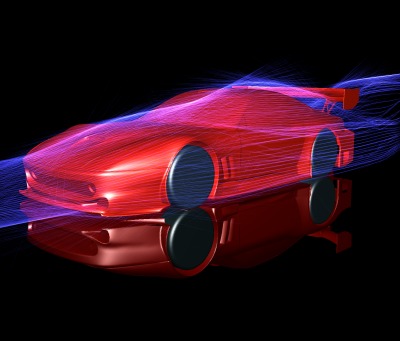

Fujiyama―CFD software calculates airflow and heat transfer and helps you visualize the otherwise invisible flow and heat. It is a tool for predicting different scenarios on computers before you create a prototype.

― Can that also be said about the sled development?

Fujiyama―Sure. A bobsled is quite expensive. As expensive as you can buy a Ferrari for the price of one bobsled. We can review designs in CFD software before actually building a bobsled.

―But the bobsled run on a computer is different from the actual run, right?

Fujiyama―That’s true. For a bobsled, in the same way as for a race car, we generally design the shape with CFD and experiments in facilities called wind tunnels. But these calculations and experiments can’t simulate the actual run perfectly. I believe the key is to understand the differences between them and how to make use of the tools, CFD and wind tunnels, in the design project.

Fujiyama―That’s true. For a bobsled, in the same way as for a race car, we generally design the shape with CFD and experiments in facilities called wind tunnels. But these calculations and experiments can’t simulate the actual run perfectly. I believe the key is to understand the differences between them and how to make use of the tools, CFD and wind tunnels, in the design project.

―Besides bobsled, what field is the CFD software used for?

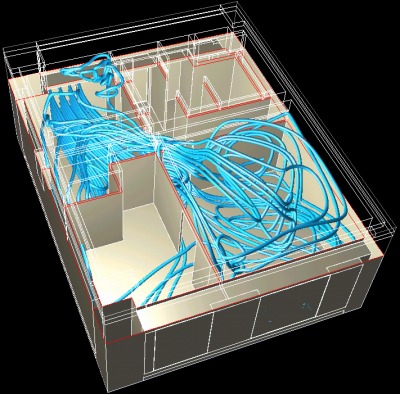

Fujiyama―As you might expect, it’s used a lot in the car industry. It’s used not only for the styling, which is meant for a better fuel efficiency, but also for the design of an air-conditioner duct, for example. More familiar products are TVs and smartphones. CFD is used for their designs. A more particular example of CFD application is a ventilation design for a classroom. You can predict how, for instance, flu viruses spread in a room with an airflow. The ventilation changes with the placement of chairs and tables, and you can simulate an airflow with the software including those environments. The software is used in the architecture field like this also.

Fujiyama―As you might expect, it’s used a lot in the car industry. It’s used not only for the styling, which is meant for a better fuel efficiency, but also for the design of an air-conditioner duct, for example. More familiar products are TVs and smartphones. CFD is used for their designs. A more particular example of CFD application is a ventilation design for a classroom. You can predict how, for instance, flu viruses spread in a room with an airflow. The ventilation changes with the placement of chairs and tables, and you can simulate an airflow with the software including those environments. The software is used in the architecture field like this also.

About the “Shitamachi Bobsleigh”

―Software Cradle has been in charge of the aerodynamics since Unit 1 of the “Shitamachi Bobsleigh”. Can you tell me about the previous units in aerodynamics perspective?

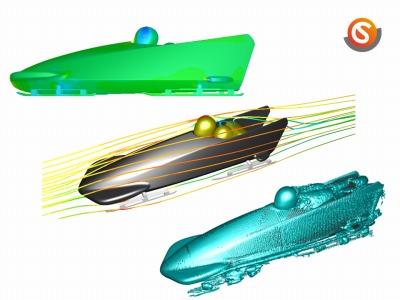

Fujiyama―For Unit 1, we fumbled our way from no experience. First we borrowed a sled from Sendai University and studied how we could reduce air drag from it by CFD software simulations. As we tried our best for the aerodynamics performance within the regulations of the bobsled competition, we ended up with the largest sled size possible but a 15% improvement in aerodynamic performance. That amounted to 0.5 seconds reduction in a ride time, theoretically.

Fujiyama―For Unit 1, we fumbled our way from no experience. First we borrowed a sled from Sendai University and studied how we could reduce air drag from it by CFD software simulations. As we tried our best for the aerodynamics performance within the regulations of the bobsled competition, we ended up with the largest sled size possible but a 15% improvement in aerodynamic performance. That amounted to 0.5 seconds reduction in a ride time, theoretically.

Next, for Unit 2, we aimed for downsizing and weight saving, and developed a design with those restrictions. Then, for the current new model, we had a concept for it in the early spring. The design was further rubbed up when the technical director of Jamaican National Team came to Japan and joined us for the review of the sled shape. The director had an experience in developing a sled in collaboration with BMW and the whole process was thought-provoking.

―For the third generation new model of the “Shitamachi Bobsleigh”, a lot of time and effort were put in to simulations.

Fujiyama―For this time, we came back to our source and carried out a deep and thorough research for aerodynamics. We also visited Ota District more often than ever to spend a lot of time discussing the design improvements with the engineers of the factories there.

―Can I ask you a simple question? How much faster will the sled be in an actual competition if you can reduce air drag by 10% using CFD?

Fujiyama―The 10% reduction means roughly 10 Newton, or 1 kilogram of air drag. According to a research, 3% reduction makes the time 0.1 second faster. In a world competition, that 0.1 second makes the difference between winning and losing, so we want to be particular about small details.

About the job

―Mr. Fujiyama, what made you choose this job?

Fujiyama―I’d wanted to build a race car since I was in high school. So I chose a university with science and engineering department, went to the graduate school, and found a job at a company that developed race cars. After that, I joined the current company that is a CFD software developer where I can build on my experience. What I like about the current job is visualizing flows which you can’t actually see with your eyes.

―What is your daily work like?

Fujiyama―My main responsibility is to provide technical support to the users of our software. We don’t just support the operations of the software but also provide a kind of consulting on how to make use of the software in the design process.

―Are you in front of a PC all the time, then?

Fujiyama―Though many of my colleagues are actually in front of a PC all day, which is understandable in a computer software company, I tend to wander in and out of the office, talking to the colleagues. I could be coordinating with a sales engineer, consulting with a software developer, sometimes grumbling about the software (laughter). Communications are important, aren’t they?

―I heard, for the aerodynamics calculation of the bobsled, it took a week or so with a supercomputer.

Fujiyama―The current calculation task for the bobsled might have taken a week for a supercomputer in a university 10 years ago. Now, however, we can perform the same task in a few hours using a computer in a private company. Anyhow, we examined a variety of sled shapes for this aerodynamics design of the bobsled in a short period of time, we ended up running a full-capacity operation of a system of many computers for over one week.

―Was there anything that especially caught your attention through the aerodynamics design of the bobsled, or was there anything you could get out of it and apply to your daily work?

Fujiyama―I could use the new software product and set an example of its positive use, as it can be hard to introduce new methods in daily work. Also, I believe I had a very good experience in explaining a fluid analysis to those who are unfamiliar with the subject and having fruitful discussions in the design phase. I could take advantage of the visually user-friendly aspect of the CFD software and it was very effective.

Fujiyama―I could use the new software product and set an example of its positive use, as it can be hard to introduce new methods in daily work. Also, I believe I had a very good experience in explaining a fluid analysis to those who are unfamiliar with the subject and having fruitful discussions in the design phase. I could take advantage of the visually user-friendly aspect of the CFD software and it was very effective.

Software Cradle Co., Ltd.

Software Cradle is a group of software engineers who specialize in fluid analysis (CFD) among the CAE (Computer-Aided Engineering) systems. The company provides coherent services from the development of CFD software to the sales and consultation. The company’s software products are used as vital design support tools in the design departments of automobile, electronics, aviation, and building industries among others. The company has provided services to many enterprises in the manufacturing and building industries and has been credited with its high-quality products and services both domestically and internationally to receive a number of engineering awards.

Software Cradle is a group of software engineers who specialize in fluid analysis (CFD) among the CAE (Computer-Aided Engineering) systems. The company provides coherent services from the development of CFD software to the sales and consultation. The company’s software products are used as vital design support tools in the design departments of automobile, electronics, aviation, and building industries among others. The company has provided services to many enterprises in the manufacturing and building industries and has been credited with its high-quality products and services both domestically and internationally to receive a number of engineering awards.